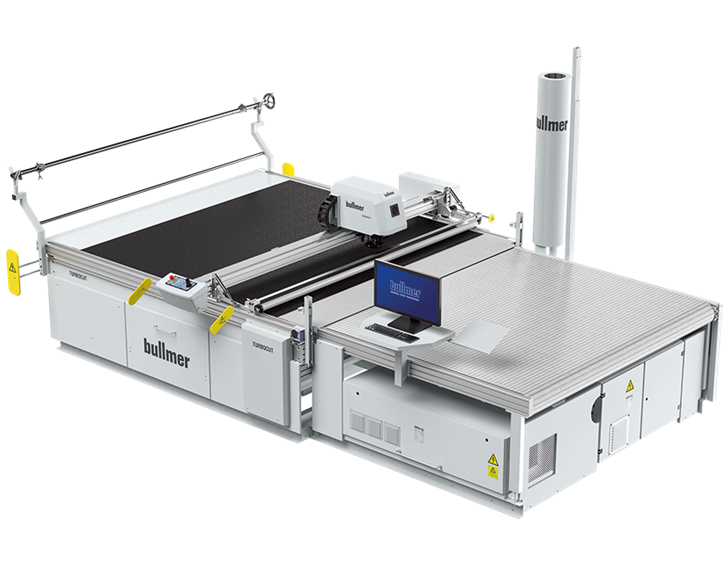

At NEDLOG, we are excited to announce the arrival of our new Bullmer Turbocut D 2501 CV.

A major step forward in expanding our cutting capabilities and strengthening our technological leadership. This system enables us to process materials faster, more precisely, and more efficiently than ever before.

The Turbocut D 2501 CV is engineered for high-performance industrial production and includes an impressive range of advanced technical features:

Technical Specifications

- Traveling conveyor system, prepared for future expansion

- Module for unwinding sealing film over the cutting window

- Pressing rollers in the unloading area for smooth material flow

- Integrated 17.5 kW vacuum turbine for exceptional hold-down performance

- Integrated cleaning device for continuous cutting quality

- Built-in air outlet with silencer for reduced noise

- Bi-directional transport of the cutting window

- High-performance cutting head equipped with an oscillating cutting blade

- Automatic knife sharpening and oiling system

- Integrated noise-suppression technology

- Operated via Windows-based control system

- Cutting height after compression: 25 mm

- Cutting window dimensions: 1,800 mm × 1,800 mm

- Maximum speed: up to 90 m/min

- Maximum acceleration: up to 1.3 g

Investing in the Future

This new bullmer reflects NEDLOG’s ongoing commitment to innovation. By continually investing in the newest technological developments, we ensure optimal efficiency, precision, and quality across our entire production workflow. The Turbocut D 2501 CV positions us to stay at the forefront of our industry, now and in the years to come.